Related posts

- By Import Diesel

- Posted on

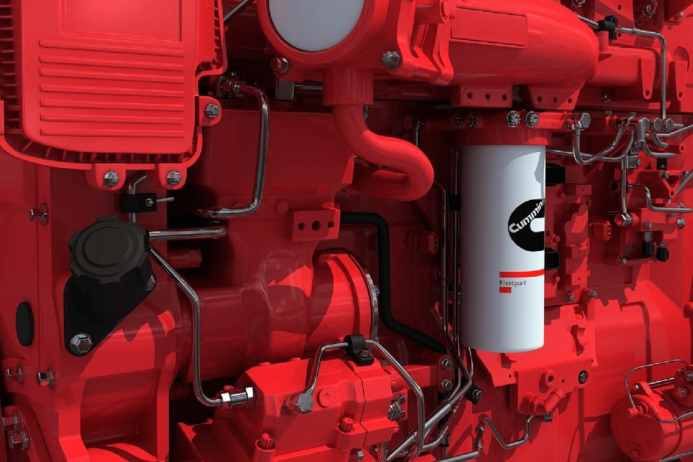

Discovering Cummins Engines: A Diverse Range of Power Solutions

Are you curious about the world of Cummins engines? This renowned manufacturer offers a broad spectrum of engines, catering to various applications and market ...

- By Import Diesel

- Posted on

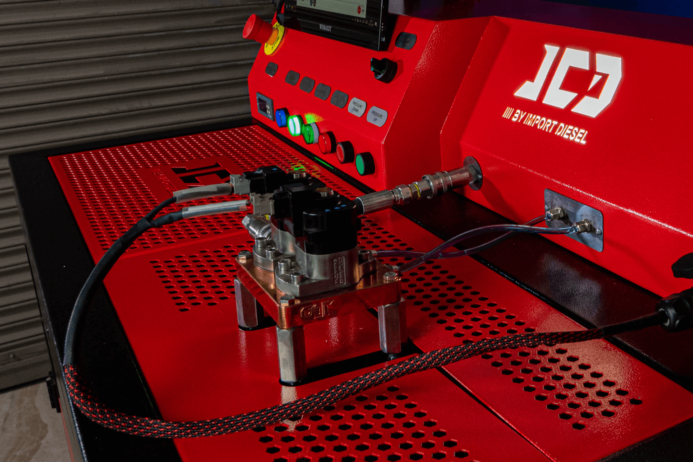

Unleashing Unmatched Power: Cummins Models Dominating the Engine Market

Are you in search of pure power and unparalleled performance? Dive into the fascinating world of Cummins engines and explore the most powerful models ...